This version (11 Jul 2013 08:37) was approved by Dragos Bogdan.The Previously approved version (28 Jan 2013 08:39) is available.

This version (11 Jul 2013 08:37) was approved by Dragos Bogdan.The Previously approved version (28 Jan 2013 08:39) is available.

This is an old revision of the document!

The AD719X family is composed of a low noise, complete analog front end for high precision measurement applications. It contains a low noise, 24-bit sigma-delta (Σ-Δ) analog-to-digital converter (ADC). The on-chip low noise gain stage means that signals of small amplitude can interface directly to the ADC.

The on-chip channel sequencer allows several channels to be enabled simultaneously, and the AD719X sequentially converts on each enabled channel, simplifying communication with the part. The on-chip 4.92 MHz clock can be used as the clock source to the ADC or, alternatively, an external clock or crystal can be used. The output data rate from the part can be varied from 4.7 Hz to 4.8 kHz.

The device has a very flexible digital filter, including a fast settling option. Variables such as output data rate and settling time are dependent on the option selected. The AD7193 also includes a zero latency option.

AD7190 operates with 5 V analog power supply and a digital power supply from 2.7 V to 5.25 V. It consumes a current of 6 mA. It is housed in a 24-lead TSSOP package.

AD7192 operates with a power supply from 3 V to 5.25 V. It consumes a current of 4.35 mA. It is housed in a 24-lead TSSOP package.

AD7193 operates with a power supply from 3 V to 5.25 V. It consumes a current of 4.65 mA, and it is available in a 28-lead TSSOP package and a 32-lead LFCSP package.

AD7194 operates with a power supply from 3 V to 5.25 V. It consumes a current of 4.65 mA, and it is housed in a 32-lead LFCSP package.

AD7195 operates with a 5 V analog power supply and a digital power supply from 2.7 V to 5.25 V. It consumes a current of 6 mA. It is housed in a 32-lead LFCSP package.

The goal of ADI Microcontroller No-OS is to be able to provide reference projects for lower end processors, which can't run Linux, or aren't running a specific operating system, to help those customers using microcontrollers with ADI parts. ADI No-OS offers generic drivers which can be used as a base for any microcontroller platform and also example projects which are using these drivers on various microcontroller platforms.

For more information about ADI No-OS and supported microcontroller platforms see: no-OS

The source code for AD719X driver can be found here:

The driver also uses the ADI util library, so make sure you also add the necessary files in your project. The source code for the util library can be found here:

The driver contains three parts:

The Communication and GPIO drivers have a standard interface, so the AD719X driver can be used exactly as it is provided.

For SPI Communication there are three functions which are called by the AD719X driver:

SPI driver architecture

For GPIO control there are seven functions which are called by the AD719X driver:

For SPI and GPIO usage there are four data types that have to be defined:

Source code documentation for the driver is automatically generated using the Doxygen tool and it is available below:

In order to be able to use the device, you will have to provide the initial parameters for the communication protocol as for the device - spi initial parameters, gpio MISO initial parameters, gpio SYNC initial parameters, polarity, gain, operating mode, data rate code, clock source, input mode, buffer option, bpdsw mode and chip id. The first API to be called is ad719x_init. Make sure that it returns 0, which means that the device was initialized correctly. ad719x_init also performs a soft reset, by calling ad719x_reset, in order to put the device in a known state.

By calling ad719x_range_setup, driver sets polarity and gain of the device. Accepted values for gain:

By calling ad719x_output_rate_select, driver sets the filter output data rate. Accepted values are between 1 and 1023. The output data rate can be programmed from 4.7 Hz to 4800 Hz.

By calling ad719x_buffer_select, driver sets the inputs as buffered or unbuffered.

By calling ad719x_clock_select, driver sets the clock source for the ADC. Accepted values:

By calling ad719x_set_bridge_switch, driver opens or closes the bridge power-down switch of the ADC.

By calling ad719x_set_operating_mode, driver sets ADC to the desired operation mode.

All the above configurations are done by ad719x_init, so no further configuration is needed.

Channel calibration can be done calling ad719x_calibrate and providing desired channel and calibration type.

After the specific configuration was performed as mentioned above, you can set the device in the desired measurement mode, using ad719x_set_operating_mode API. The available operation modes are:

Temperature can be read using device's internal sensor. ad719x_temperature_read API will read and convert raw value into Celsius degrees.

By using ad719x_single_conversion API, a single read of the enabled channels will occur.

By using ad719x_continuous_read_avg API, the device will read the specified number of samples and will store their average value.

For Single Conversion and Continuous Conversion Data, user can use ad719x_convert_to_volts API to transform raw value into Volts.

struct xil_spi_init_param spi_extra = {

.type = SPI_PS,

.flags = 0U

};

struct spi_init_param spi_ip = {

.device_id = SPI_DEVICE_ID,

.max_speed_hz = 1000,

.mode = SPI_MODE_3,

.chip_select = 0U,

.bit_order = SPI_BIT_ORDER_MSB_FIRST,

.platform_ops = &xil_spi_ops,

.extra = &spi_extra

};

const struct xil_gpio_init_param gpio_extra = {

.type = GPIO_PS,

.device_id = GPIO_DEVICE_ID

};

const struct gpio_init_param miso_ip = {

.number = RDY_PIN,

.platform_ops = &xil_gpio_ops,

.extra = &gpio_extra

};

const struct gpio_init_param sync_ip = {

.number = SYNC_PIN,

.platform_ops = &xil_gpio_ops,

.extra = &gpio_extra

};

/* Device AD719X instance. */

struct ad719x_dev *dev;

struct ad719x_init_param ad7190_dev_ip = {

.spi_init = &spi_ip,

.gpio_miso = &miso_ip,

.sync_pin = NULL,

.current_polarity = 1,

.current_gain = AD719X_ADC_GAIN_64,

.operating_mode = AD719X_MODE_SINGLE,

.data_rate_code = 480U,

.clock_source = AD719X_INT_CLK_4_92_MHZ,

.input_mode = 0,

.buffer = 0,

.bpdsw_mode = 0,

.chip_id = AD7190

};

ret = ad719x_init(&dev, ad7190_dev_ip);

if(ret)

return FAILURE;

HW Platform(s):

This section contains a description of the steps required to run the AD7193 demonstration project on a Digilent Cerebot MX3cK platform.

The AD7193 demonstration project for PIC32MX320F128H consists of three parts: the AD7193 Driver, the PmodAD5 Demo for PIC32MX320F128H and the PIC32MX320F128H Common Drivers.

All three parts have to be downloaded.

A PmodAD5 has to be connected to the JE connector of Cerebot MX3cK development board.

The following commands were implemented in this version of AD7193 reference project for Cerebot MX3cK board.

| Command | Description |

|---|---|

| help? | Displays all available commands. |

| reset= | Resets the AD7193. |

| polarity? | Displays the polarity value. |

| polarity= | Sets the polarity value. Accepted values: 0 - Bipolar mode. 1 - Unipolar mode. |

| range? | Displays the range value. |

| range= | Sets the range value. Accepted values: 0 - Gain=1. (Input voltage range must be +/-2500mV) 3 - Gain=8. (Input voltage range must be +/-312.5mV) 4 - Gain=16. (Input voltage range must be +/-156.2mV) 5 - Gain=32. (Input voltage range must be +/-78.12mV) 6 - Gain=64. (Input voltage range must be +/-39.06mV) 7 - Gain=128.(Input voltage range must be +/-19.53mV) |

| pseudoBit? | Displays the Pseudo Bit value (AD7193_REG_CONF). |

| pseudoBit= | Sets the Pseudo Bit Value (AD7193_REG_CONF). Accepted values: 0 - Disables the pseudo differential measuring. 1 - Enables the pseudo differential measuring. |

| register? | Displays the value of the data register (AD7193_REG_DATA) for specified channel. Accepted values: 0..7 - selected channel. |

| voltage? | Displays the voltage applied to specified channel. Accepted values: 0..7 - selected channel. |

| temperature? | Displays the temperature. |

Commands can be executed using a serial terminal connected to the UART1 peripheral of PIC32MX320F128H.

The following image shows a generic list of commands in a serial terminal connected to processor’s UART peripheral.

This section presents the steps for developing a software application that will run on the Digilent Cerebot MX3cK development board for controlling and monitoring the operation of the ADI part.

This section contains a description of the steps required to run the AD7193 demonstration project on a Digilent Cerebot MC7 platform.

Following commands were implemented in this version of AD7193 reference project for Cerebot MC7 board.

| Command | Description |

|---|---|

| help? | Displays all available commands. |

| reset= | Resets the AD7193. |

| mode? | Displays the selected operating mode. |

| mode= | Selects the AD7193's operating mode. Accepted values: 0 - 3. |

| pseudo? | Displays the Pseudo Bit value (AD7193_REG_CONF). |

| pseudo= | Sets the Pseudo Bit Value (AD7193_REG_CONF). Accepted values: 0, 1. |

| channel? | Displays the enabled channel. |

| channel= | Enables one channel on the AD7193. Accepted values: 0 – 7. |

| data? | Initiates a conversion and displays the value of the data register (AD7193_REG_DATA). |

| voltage? | Initiates a conversion and displays the voltage applied to enabled channel. |

| temperature? | Displays the temperature. |

Commands can be executed using a serial terminal connected to the UART1 peripheral of dsPIC33FJ128MC706A.

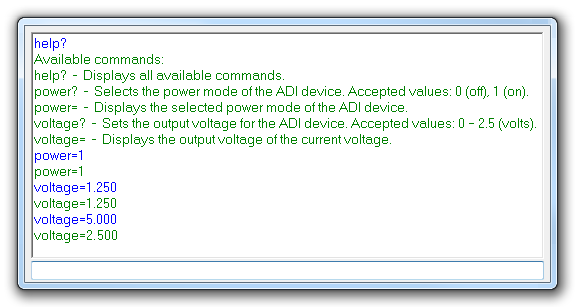

The following image shows a list of commands in a serial terminal connected to processor’s UART peripheral.

This section presents the steps for developing a software application that will run on the Digilent Cerebot MC7 development board for controlling and monitoring the operation of the ADI part.

This section contains a description of the steps required to run the AD7193 chipKIT demonstration project on a Digilent Cerebot MX3cK platform.

Following commands were implemented in this version of AD7193 chipKIT reference project for Cerebot MX3cK board.

| Command | Description |

|---|---|

| help? | Displays all available commands. |

| reset= | Resets the AD7193. |

| mode? | Displays the selected operating mode. |

| mode= | Selects the AD7193's operating mode. Accepted values: 0 - 3. |

| pseudo? | Displays the Pseudo Bit value (AD7193_REG_CONF). |

| pseudo= | Sets the Pseudo Bit Value (AD7193_REG_CONF). Accepted values: 0, 1. |

| channel? | Displays the enabled channel. |

| channel= | Enables one channel on the AD7193. Accepted values: 0 – 7. |

| data? | Initiates a conversion and displays the value of the data register (AD7193_REG_DATA). |

| voltage? | Initiates a conversion and displays the voltage applied to enabled channel. |

| temperature? | Displays the temperature. |

Commands can be executed using the serial monitor.

Carriage return has to be selected as a line ending character. The required baud rate is 9600 baud.

The following image shows a list of commands in the serial monitor.

This section presents the steps for developing a chipKIT application that will run on the Digilent Cerebot MX3cK development board for controlling and monitoring the operation of the ADI part.