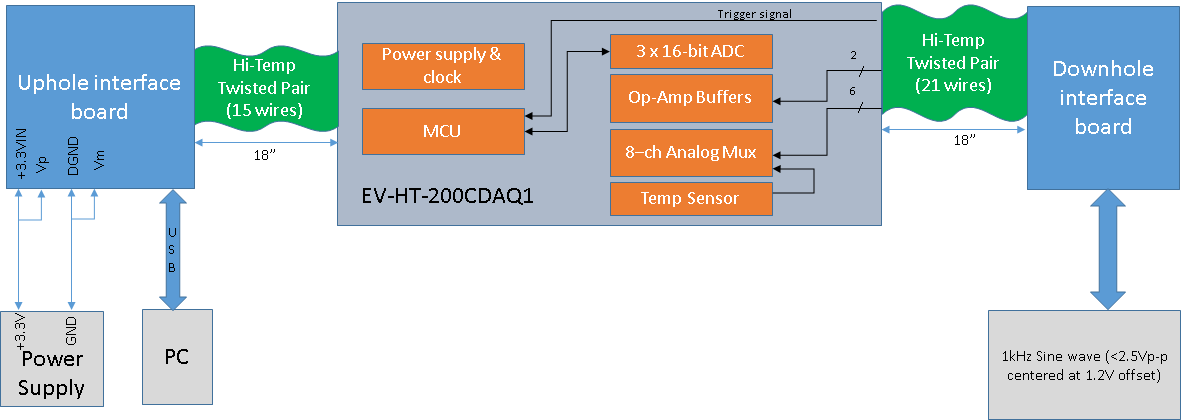

The EV-HT-200CDAQ1 reference design kit includes a high temperature circuit assembly with data acquisition front-end and microcontroller, optimized firmware, data capture and analysis software, source code, design files, bill of materials, test reports, and breakout boards. This platform is suitable for reference design, rapid prototyping and lab testing of high temperature instrumentation systems. The dimensions and construction of the circuit assembly have been designed to be compatible with oil and gas instrumentation form factors, although it can also be used as the basis for other high temperature applications. A block diagram of the main board is shown below. For a detailed overview of the platform features, see the overview wiki page.

This document is intended to provide instructions on how to connect and use the main features of the evaluation board. For more detailed information on the software features, organization, hardware design notes and other useful information refer to the main wiki page.

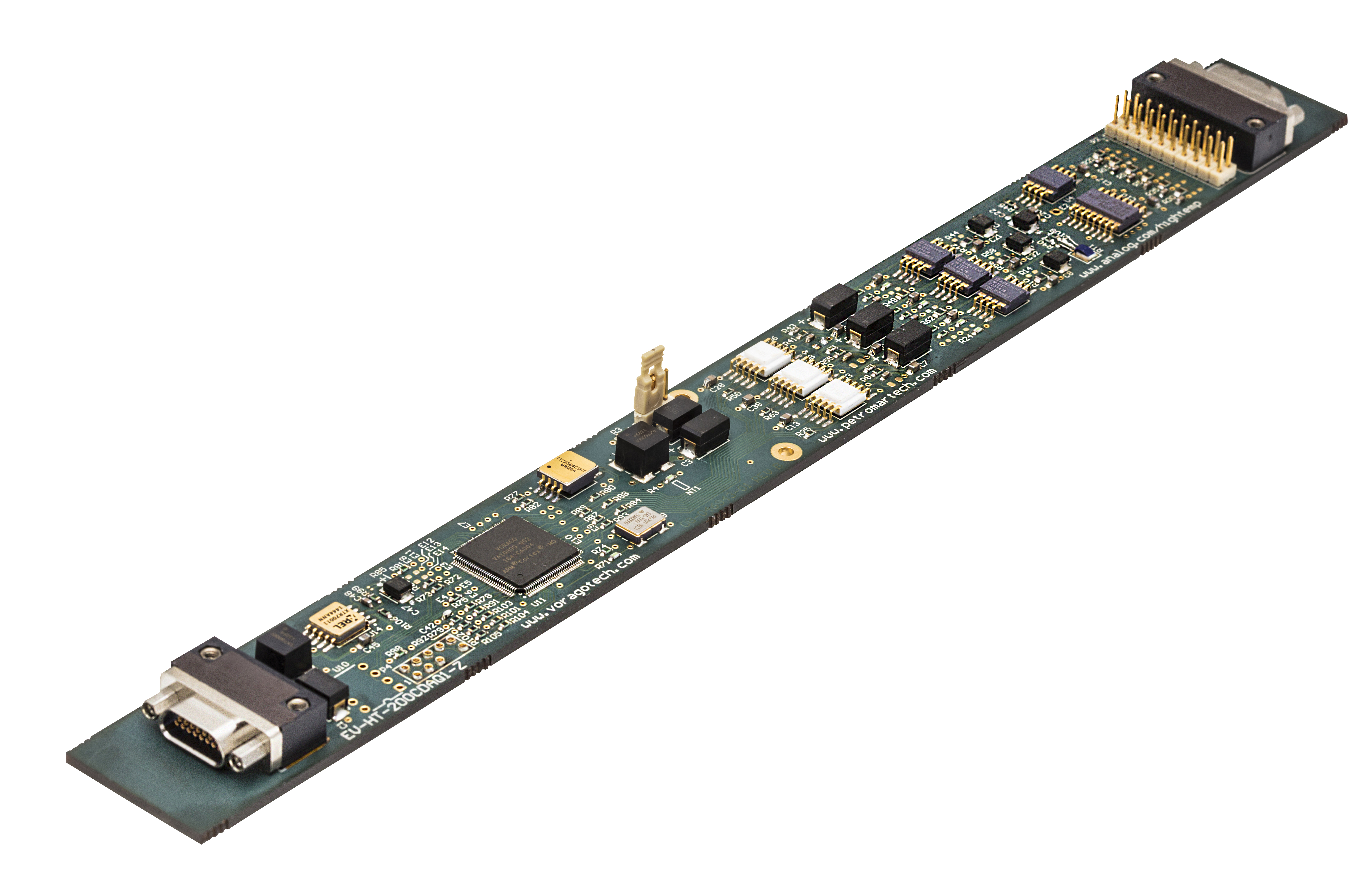

The main EV-HT-200CDAQ1 reference design board is pictured below:

In addition to this main board, the following supporting boards are included in the kit:

supplies.

There are two main software components incorporated in this project the VA10800 ARM microcontroller firmware, and the Data Viewer host software.

All EV-HT-200CDAQ1 boards come with the microcontroller pre-programmed. The latest firmware can be downloaded and built by downloading it from ADI's GitHub. See the software download wiki page for further details. The firmware is programmed with multiple, highly configurable modes of data acquisition. Acquired data is sent to a PC via the UART interface.

The Data Viewer host software (and open source) can be downloaded from the software download wiki page. This software communicates with the main board via UART to control acquisition modes, display data, log data and run signal analysis.

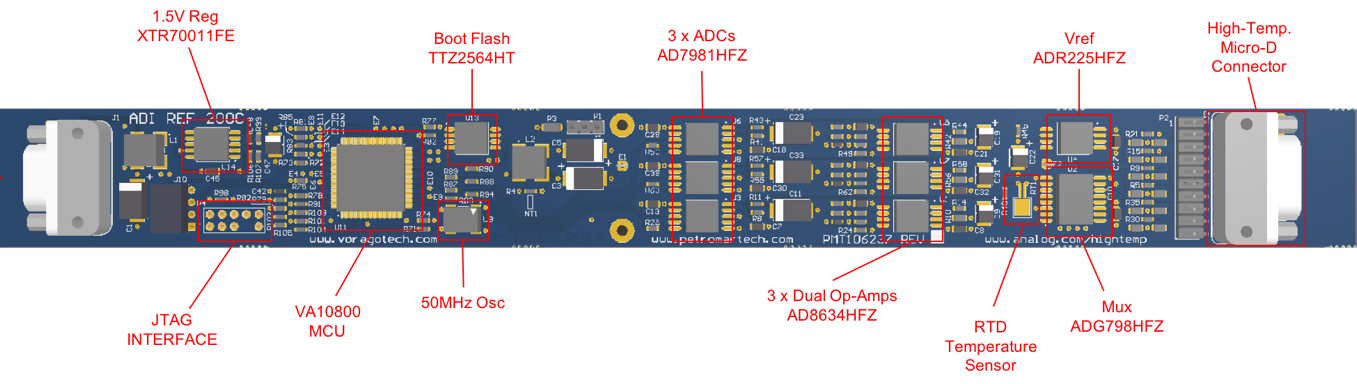

The image below is a quick reference for main component placement on the main board. Consult the schematic in the design package for more detailed information.

To assist with quickly finding which pins are tied to the various connectors on the board, the following set of tables are provided. Refer to the schematic for IC connection details.

Prior to running the HT DAQ viewer software and measuring precision signals, it is recommended that the communication channels be checked ste-by-step using the minimum connection as described in the steps below. Refer to the diagram below for guidance on connections. PuTTY, free terminal software, is used in this hardware check. If you do not have this program installed, you can download it at http://www.putty.org.

HT DAQ Viewer is a Windows application that allows the user to connect, control, view and log captured data from the EV-HT-200CDAQ1 reference design board. It has advanced signal analysis functions built in including FFT, histogram, and spectrum analysis to facilitate deep data examination. Source code for HT DAQ Viewer in C# is available on the ADI GitHub, see the software download wiki page for more information.

HT DAQ Viewer is a “zero install” executable. Download the latest version of the software from the software download wiki page. Unzip the archive in a directory of your choice. Click on the “HT DAQ Viewer.exe” to run the program. If you want to have a shortcut on your desktop or another folder, right click on the “HT DAQ Viewer.exe” and select “create shortcut” and place this link where desired.

The board should be properly connected, and powered-ON as described in the previous section. Connect the USB cable included in the kit from the PC to the Power/Comm breakout board. The breakout board will instantiate as a COM port in the Windows Device Manager as shown in the below diagram. Note the port number.

Start the application, enter the COM port number then click the “Connect” button.

Upon connection, the board firmware information will be displayed in the “About” tab dialog. This is the easiest way to show the kit is powered up and communicating with the PC.

Data is captured by the EV-HT-200CDAQ1 firmware in two different modes, Burst Mode or Continuous Mode.

In Burst Mode, the firmware allows for a high sample rate (minimum = 2.4 microseconds) capture for short intervals. Specific channels and rates are manually set. In Continuous Mode, all channels are sampled sequentially at a fixed sample period of approximately 10 microseconds, as shown in below diagram. A full sequence is conducted at a periodic rate set by the user. In both modes, data is transmitted over the UART interface to the HT DAQ Viewer for both display and analysis.

In Burst Mode, the firmware will:

This process is done on either a ‘single shot’ or ‘periodic’ basis as specified by the user. Any combination of channels can be selected. The 16Kbyte buffer will be equally shared among selected channels as shown in the below table.

Channels 0 and 1 capture data simultaneously on ADC units 0 and 1. Channels 2 to 9 are multiplexed and will capture data sequentially on ADC unit 2. The multiplexor and associated buffer require additional time for the signal to settle before it can be accurately converted. When using more than one multiplex channel, keep the sample rate above 4 microseconds. If only one mux channel is selected, then there is no multiplexor switching action performed during the burst acquisition on ADC unit 2 and the minimum sample period is 2.4 microseconds. ADC’s 0 and 1 samples are acquired first followed by ADC2. At the end of each burst mode experiment channels 8 and 9 are sampled 4 times and averaged for a VCC and RTD reading. ADC’s 0 and 1 are then acquired for the full burst period followed by ADC2. An example timeline for a burst mode experiment with multiple channels selected is shown below.

To execute a burst mode acquisition, set up the channel and period parameters then click the “Start Acquisition” or “Single Shot” button. The following screen captures are for an example acquiring a 1 kHz sine waveform on CH0 at 400ksps for 8192 samples and repeating this every 2 seconds.

An AC Analysis and Histogram is automatically performed when only a single channel is selected and “burst mode” is run. The figure below shows the results for a 1 kHz sine wave.

While on the FFT Tab, you can use the Windows Copy (CTRL-C) to save a snapshot of the AC analysis data into the Windows Clipboard. This data can then be Pasted (CTRL-P) from the Windows Clipboard to an Excel spreadsheet or as text in a text editor like Notepad. Shown is an example of 7 Copy and Paste actions into Excel from the AC analysis window.

A histogram example from a 1 kHz sine wave is shown here.

Continuous mode will sequentially sample all channels (0 to 9) at the sample period set in the “Sample Period” window. It is enabled by checking the Enabled checkbox in the Continuous mode dialog box. The samples will commence when the “Start Acquisition” box is clicked. The data is sent continuously to the HT DAQ Viewer application for live display. All ten channels are acquired, but only eight graphs are displayed as CH8 (VCC) and CH9 (RTD) are displayed on the left pane as Board Temperature and VCC.

It is possible to conduct sampling when an external trigger signal is applied. The channel setup is the same but the experiment period must be set to 0 and an external signal applied to GPIOB14 on the analog breakout board. When the trigger goes active, the selected ADC channels will be sampled. The delay from the signal going active (high) before the first sample occurs will be under 20 microseconds.

The data captured from a single experiment can be exported to a CSV (comma separated variable) file by clicking the “Export to CSV” button. Data format is as shown in italics below. The first five lines contain experiment information. The subsequent lines (>8k) have the conversion information in floating point format with a trailing comma on each line.