This version (13 Jun 2017 12:14) is a draft.

This version (13 Jun 2017 12:14) is a draft.

This is an old revision of the document!

CN0349 provides robust and complete solution for processing conductivity and temperature inputs into digital code. The design solution is optimized for high precision and low cost measurement, using five active devices, and has a total error less than 1% FSR after calibration. The output of the circuit is fully isolated, and therefore, the ground-loop interference is effectively reduced, making it ideal for industrial applications.

The circuit shown in Figure 1 incorporates the AD5934YRSZ 12 bit Impedance Converter, ADG715BRUZ Octal SPST Switch, AD8606ARZ Rail-to-Rail OpAmp, ADuM5000ARWZ Isolated DC-DC Converter, ADuM1250ARZ Dual I2C Isolator, to convert the conductivity and temperature inputs to digital code.

The circuit has 8pin Digilent Pmod I2C interface connector on board, which could be used for connection to a customer microprocessor or FPGA.

The CN0349 circuit note discusses the design steps needed to optimize the circuit shown in Figure 1 for a specific measuring range including accuracy analysis and component selection considerations.

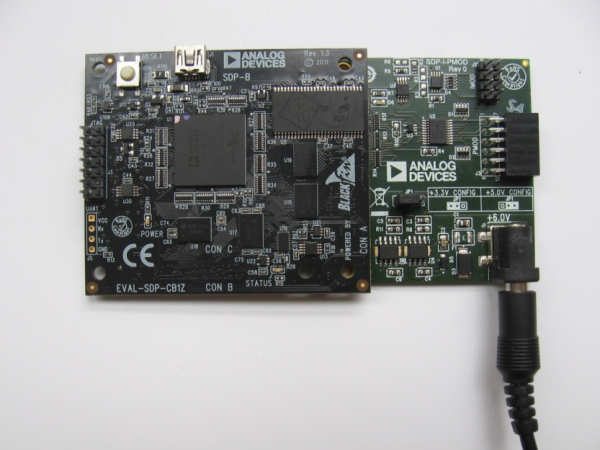

The performance of the circuit could be demonstrated with the use of Analog Devices SDP controller EVAL-SDP-CB1Z and SDP-to-PMOD Interposer Board SDP-PMD-IB1Z, both optional purchase items.

This user guide discusses the use of the evaluation software to collect data from the EVAL-CN0349-PMDZ Evaluation Board CN0349

Figure 1. Data Acquisition system for conductivity measurements with isolation (All connections and Decoupling Not Shown)

NOTE: It is recommended that you install the CN0349 Evaluation Software to the default directory path C:\Program Files\Analog Devices\CN0349\ and all National Instruments products to C:\Program Files\National Instruments\

NOTE: It is recommended that you close all other applications before clicking “Next”. This will make it possible to update relevant system files without having to reboot your computer.

\\

It is recommended that you install the drivers to the default directory path

C:\Program Files\Analog Devices\SDP\DriversR2

—-

NOTE: Make sure that the jumper is positioned as shown below!

}}

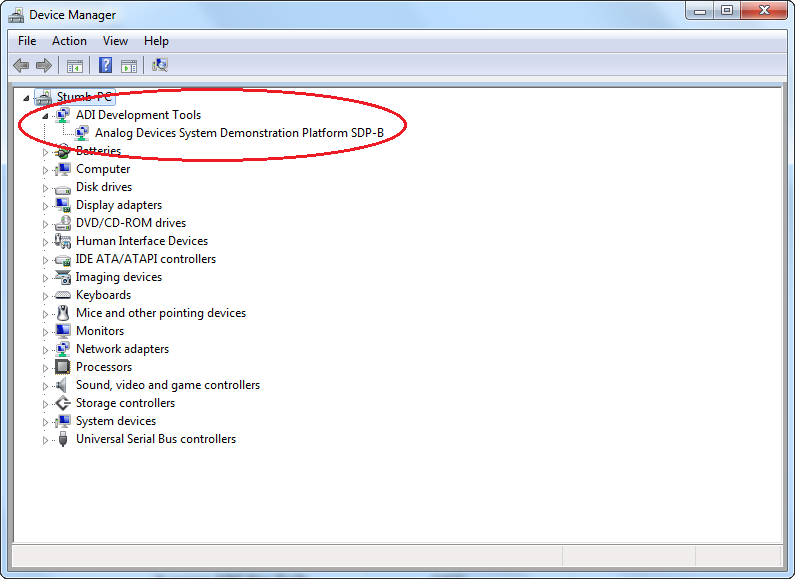

}} NOTE: Verify that the SDP Drivers are loaded properly. For that purpose open the Device manager and check if the SDP Board is recognized. If not repeat steps 1-3

Inactive

Inactive Busy

Busy Error

Error Waiting for user action

Waiting for user action

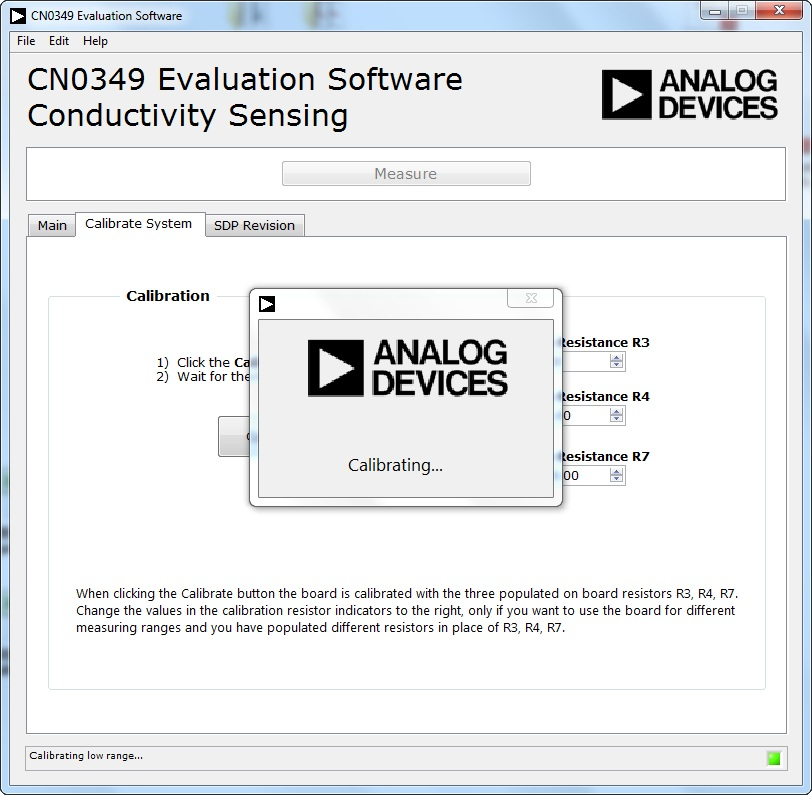

NOTE: If the software was installed to the default location it will be found at

C:\Program Files\Analog Devices\CN0349\CN0349.exe

This Chapter will describe how to use the CN0349 board with a customer platform other than the SDP-B platform. In this section we refer to customer platform the “host”. The host can be a MCU platform, FPGA platform, or PC with USB to I2C converter, or any type of programmable platform which has an I2C interface.

For the detailed specifications of the I2C interface, please check: I2C-bus specification. Notice that the CN0349 board does not support all the feastures of the I2C-bus specification, and the limitations will described later.

The EVAL-CN0349-PMDZ evaluation board uses a standard Dignlent Pmod 8pin I2C connector interface, J2, to communicate with the host. For the detailed Digilent Pmod interface specification please check: Digilent Pmod Interface Specification

The CN0349 board can accept both +3.3V±10% or +5V±10% power supplies. Please make sure the host has the same I/O level standard as the CN0349 board. The power supply for the CN0349 board minimum current requirement is 300mA. The power supply for CN0349 must provide this current with minimum voltage drop. Otherwise the permanent damage of CN0349 may occur.

For the customer platform to communicate with the CN0349 board, the I2C communication protocol must be designed carefully. The maximum I2C speed and timing is limited by the ADG715 and the AD5934. Please check the data sheet for the AD5934 and ADG715 for more specific details. The host I2C timing and speed must meet with the requirements of both the ADG715 and AD5934. The maximum I2C clock speed for ADG715 and AD5934 is 400kHz.

Caution: In the EVAL-CN0394-PMDZ evaluation board, the ADG715 I2C address is set to: 0x48, and the AD5934 I2C address is: 0x0d. Please make sure in the host I2C bus there are no devices that have same address as the ADG715 and AD5934.

In the host software the AD5934 following settings must be observed, otherwise the results may incorrect:

In the host software the ADG715 register must be set to one of following conditions, otherwise incorrect results may occur:

The CN0349 board must be calibrated before measurement. The calibrations theory and calculations are located in circuit note CN0349.

The following shows the two allowable ranges for the conductivity cell admittance. If the conductivity cell admittance is out of these ranges, incorrect results may occur. Please note: the admittance of the cell is not the conductivity of the cell, the cell constant must be used to convert the admittance to conductivity. For the details of the cell constant please check circuit note CN0349.

Please note that the measurement result is the YX not YCELL. the details of converting YX to YCELL are give in CN0349.

The hardware limitations in the CN0349 board need to be considered carefully. If other settings for AD5934 and ADG715 outside the limits described above are used, the AD5934 ADC input must not be saturated. The AD5934 ADC reference is AVDD2=3.3V which determines the input range. The AD5934 ADC input signal amplitude is a function of the excitation voltage, the RC filter made up of R1, R5, C1, the ADG715 setting, the admittance of conductivity cell, and the AD5934 internal PGA gain settings. Incorrect results will be obtained if any of these factors cause the AD5934 ADC input signal to go out of range.