CN0295: Flexible, 4 mA-to-20 mA Pressure Sensor Transmitter with Voltage or Current Drive

OVERVIEW

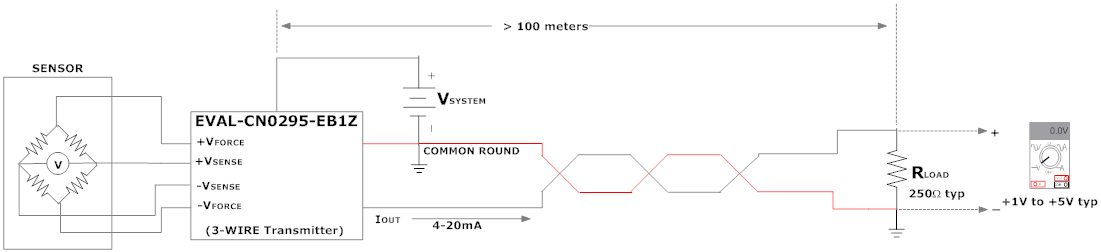

The circuit is a flexible current transmitter that converts the differential voltage output from a pressure sensor to a 4 mA-to-20 mA current output. The circuit is optimized for a wide variety of bridge-based voltage or current driven pressure sensors, utilizes only five active devices, and has a total unadjusted error of less than 1%. The power supply voltage can range from 7 V to 36 V depending on the component and sensor driver configuration. The input of the circuit is protected for ESD and voltages beyond the supply rail, making it ideal for industrial applications.

DEMO REQUIREMENTS

-

+7V to +24V power supply or equivalent power supply

Precision power supply

Agilent 3458A or equivalent Current meter

Differential Pressure sensor or Equivalent Dual channel DC Signal Source

HARDWARE SETUP

Power Supply

In order for the circuit to operate properly, the supply voltage, must be greater than 7

V in order to provide sufficient headroom.

Using Actual Sensor

A differential output bridge type sensor should be attached to a 4 channel screw terminal block (J3) labeled with SUPPLYSNS on the PCB.

A differential sensor gauge like from

NXP which can be used for evaluation.

Pin polarity for Vsense and for

V/Iforce should be take into consideration

The following configuration can be used to simulate the sensor characteristic for evaluation purposes.

A dual power supply can be used to power up the board from Vout1 and to generate a common-mode voltage of 2.5

V from Vout2 shown in the block diagram for test setup.

A precision voltage source generates the 0 to 100

mV differential input voltage at the in-amp input, which then simulates the sensor output shown in the block diagram for test setup.

3 kΩ at R_bridge simulates the bridge type sensor impedance.

For lower than 5 kΩ bridge resistance, the drive voltage can be decreased down to 5

V using a buffer configuration by removing resistor R6.

Sensor Drive

The circuit can be switched to the current or voltage drive configuration by moving S1 to the position labeled on the PCB.

Voltage Drive Configuration

In the voltage drive mode with VDRIVE = 10

V, the supply voltage VLOOP or system supply must be greater than 10.2

V

Current Drive Configuration

In the current drive mode, the supply voltage VLOOP or system supply must be greater than 11.2

V in order to maintain sufficient headroom.

Current drive configuration can be used for four-wire ohm circuit configuration where in the main advantage of this configuration is that the voltage is measured directly across the load cell, neglecting the load effect of the lead wires for long distance measurements.

Both for voltage and current drive mode, the minimum loop supply voltage is dependent on the configuration of the drive circuit for the bridge.

Output Measurements

The output of the system can be measured in two ways, either through direct output current measurement or voltage output through the series resistor.

* Voltage Measurement

It is important that the 2-pin male header (J1) be populated first before doing a voltage measurement across the terminal block (P1)

* Current Measurement

The system has an onboard resistor load (R14) of 500ohms that can be de-soldered to replace with a desired resistor load value

SCHEMATICS, PCB LAYOUT, BILL OF MATERIALS

Registration

Receive software update notifications, documentation updates, view the latest videos, and more when you register your hardware. Register to receive all these great benefits and more!

End of Document